Wikipedia: In business, «Gemba» refers to the place where value is created

Here: A visit to a «real» watch factory

{reading time: approx. 5 minutes – plus 35 pictures;

alternatively (only in German, though) you can watch the YouTube video here (the Formex part starting at 00:57:30): Fifth Wrist Ohne Hemmung }

In April this year, several fortunate circumstances came together to allow us to celebrate a European Fifth Wrist get-together in La Chaux-de-Fonds.

We used this opportunity to send a delegation to visit Formex – the «rising star of independent affordable watch making» as I would call it – in their new premises in Biel/Bienne.

This is a short (photo-) report of this trip for you:

Formex is the brand of owner and CEO Raphaël Granito, the son of Elio Granito, who founded Dexel – a major supplier and partner of the watch industry – over 30 years ago. So it was no surprise, that we found Formex within the Dexel building.

But this in turn held a few surprises for us.

You will find Dexel/Formex in the new dedicated 11,000 sqm building in an industrial zone on the outskirts of the city (just on the other side of the motorway you find the other commercial area with the huge Rolex factories).

The Dexel building has four storeys, one of which is currently empty and «waits» for future expansion. Parts of the first floor is where Formex resides and where we meet Raphaël and his team.

While our tour also took us into Raphaël’s office – which is very interesting as it has two doors: one towards Formex and one towards Dexel – we met in a very nice purpose-built showroom.

We started this tour with … well watches.

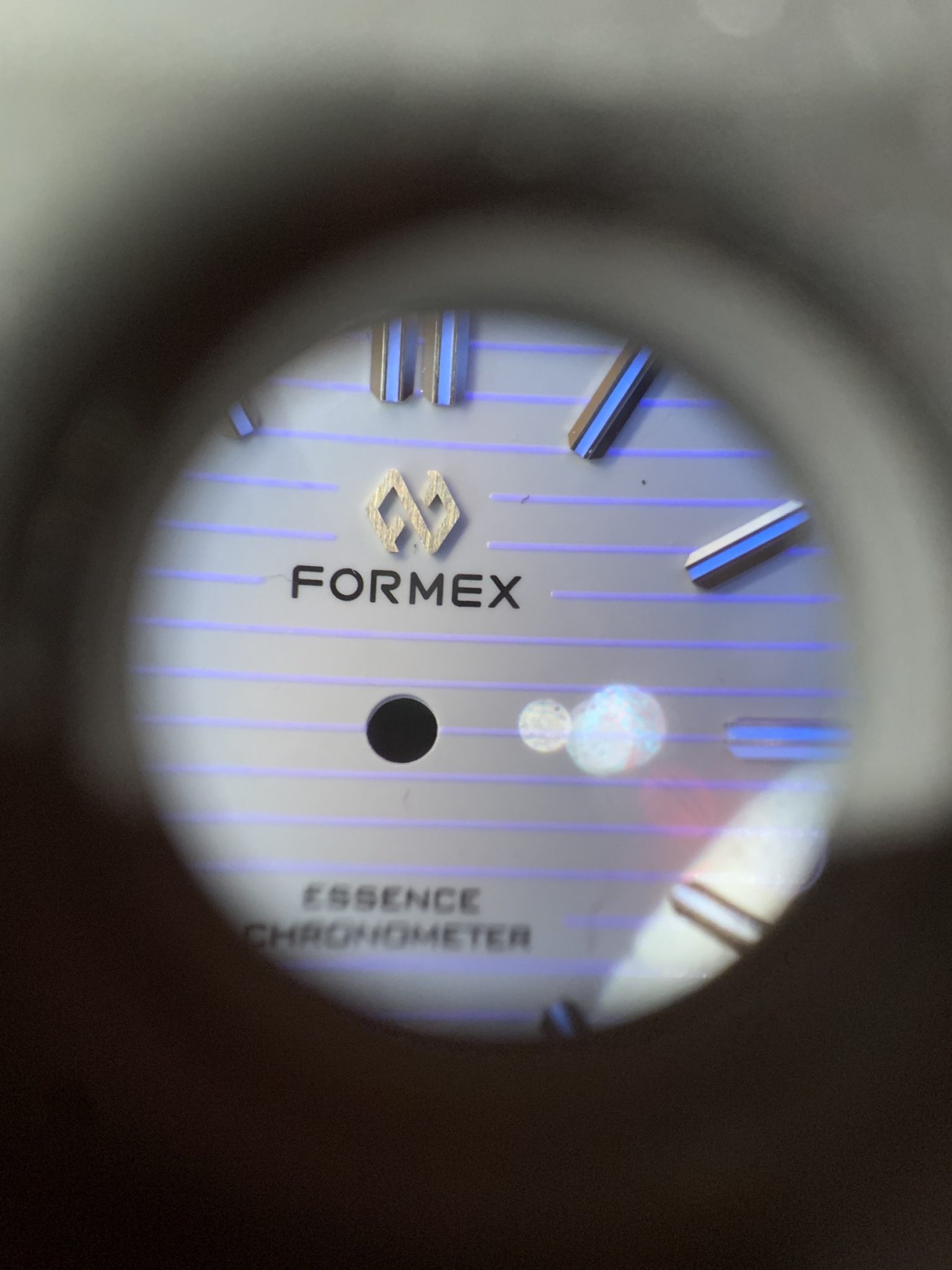

I think these watches do actually fit uns quite well. They also show one of the main – in my opinion – competitive advantages of Formex watches quite well: the dial.

Part of the family of watch companies of the Granito family is Courtedoux in the Swiss jura mountains. Being able to have this form of direct access makes it possible for Formex to not only offer Swiss made (unlike the majority of brands in this price bracket) but also innovative and very intriguing dials.

On our wrists you see a malachite dial and the sandwich dial of my favourite, the Field.

You see also a couple of sample mother-of-pearl dials in front of all the watches we tried on …

One detail I really love are the lines which feature many Formex dials – and which are not embossed but milled one by one by a CNC machine.

Often overlooked by enthusiasts: designing a new watch of course involves ideas which, for whatever reason, don’t make it into production. An example of this we see on this prototype here, where the lines are filled with lume!

But let’s now come back to the Biel factory. A short walk through the offices …

… and we arrived in the assembly area.

The kind of «boxes» in the background are so-called laminar flow boxes which take care for a dust-free environment and are quite expensive, which is why you don’t find them everywhere.

«Inside» this box you find the «usual» work bench. Here Raphaël himself opened his personal watch for us to have a look at the operation principle of the suspension system of the Essence.

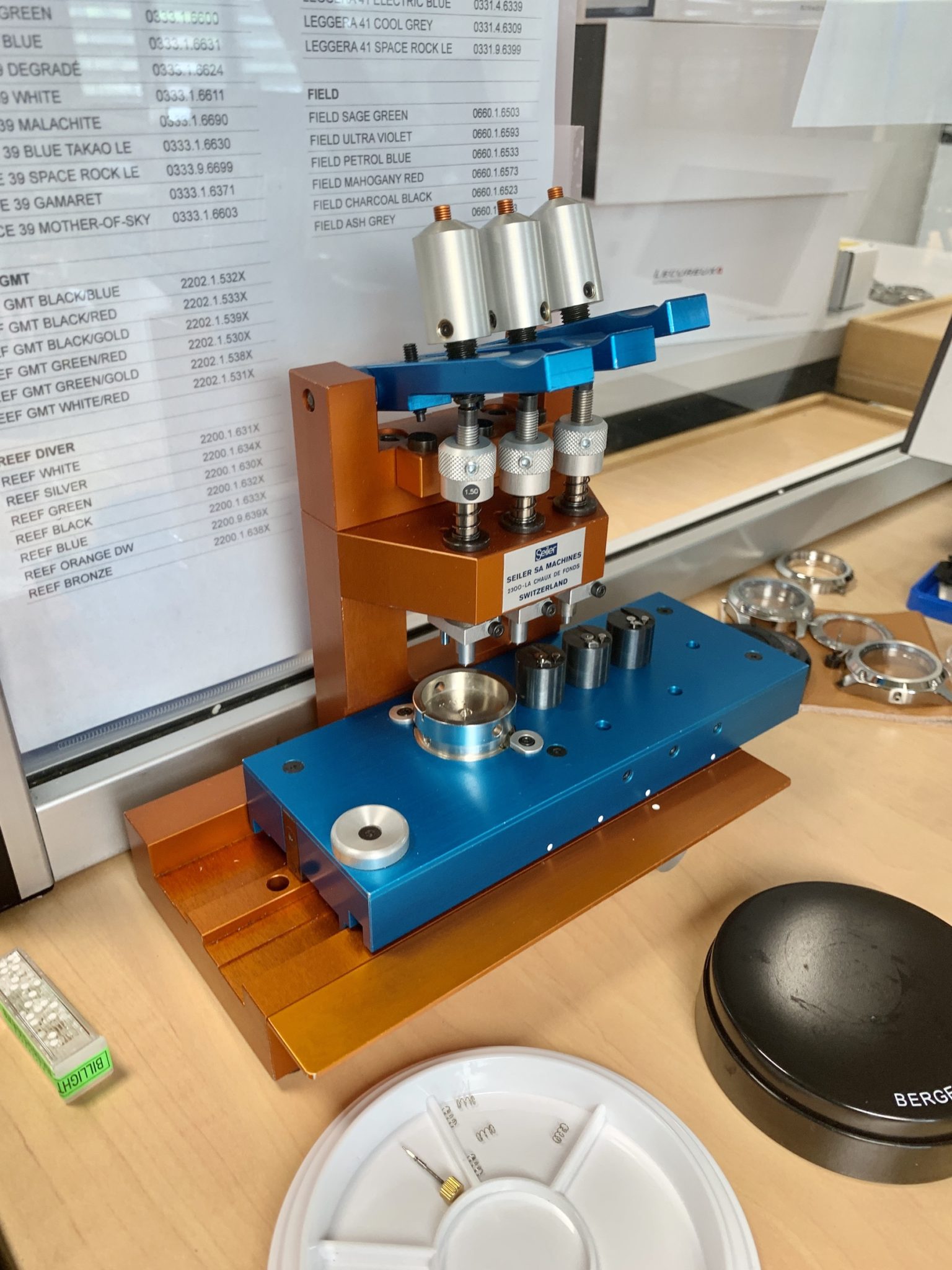

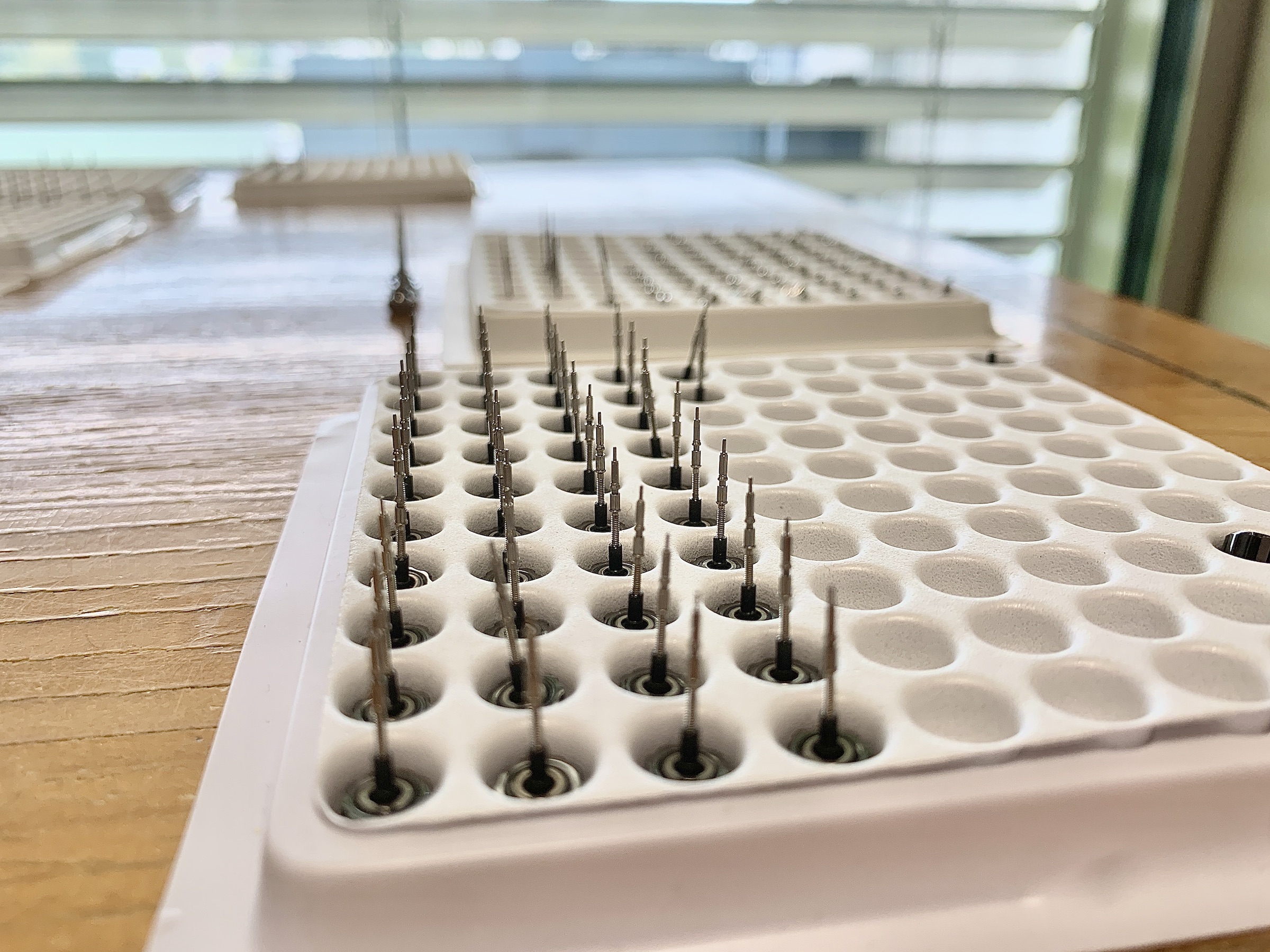

And there are a bunch of other equipment, modern and old-fashioned around there as well as lots of parts waiting to be assembled.

The last room in the Formex sector was the shipping area. Here we see the logical and physical link between Formex and Dexel: the automated storage system. This system connects all floors with each other and distributes all sorts of small and big parts – including the caps you see us wearing on the second picture 🙂

The next stage was downstairs, visiting the production area of Dexel.

With some 120 employees – 10 alone in engineering – Dexel is about 10 times bigger than Formex, offering Formex a huge range of resources for manufacturing and innovation. Dexel mainly invents, develops and manufactures cases, bracelets and clasps for many well-known customers made of all materials you can think of from gold to carbon, including ceramics.

The first thing you see if you enter the workshop tract is a door which reminded me of a bank. Which is no wonder, since this is also where the materials are delivered – and a not inconsiderable amount of gold is part of it.

You can see the bars of steel, titanium and brass on the picture (not the gold ones, they reside in a walk-in safe). It is hard to imagine that the delicate, perfectly finished parts that we will see later are created from these raw bars.

As you can see, the production area is really huge (if you wonder, why you don’t see many people: we visited late on a Friday afternoon in order not to interfere with the work).

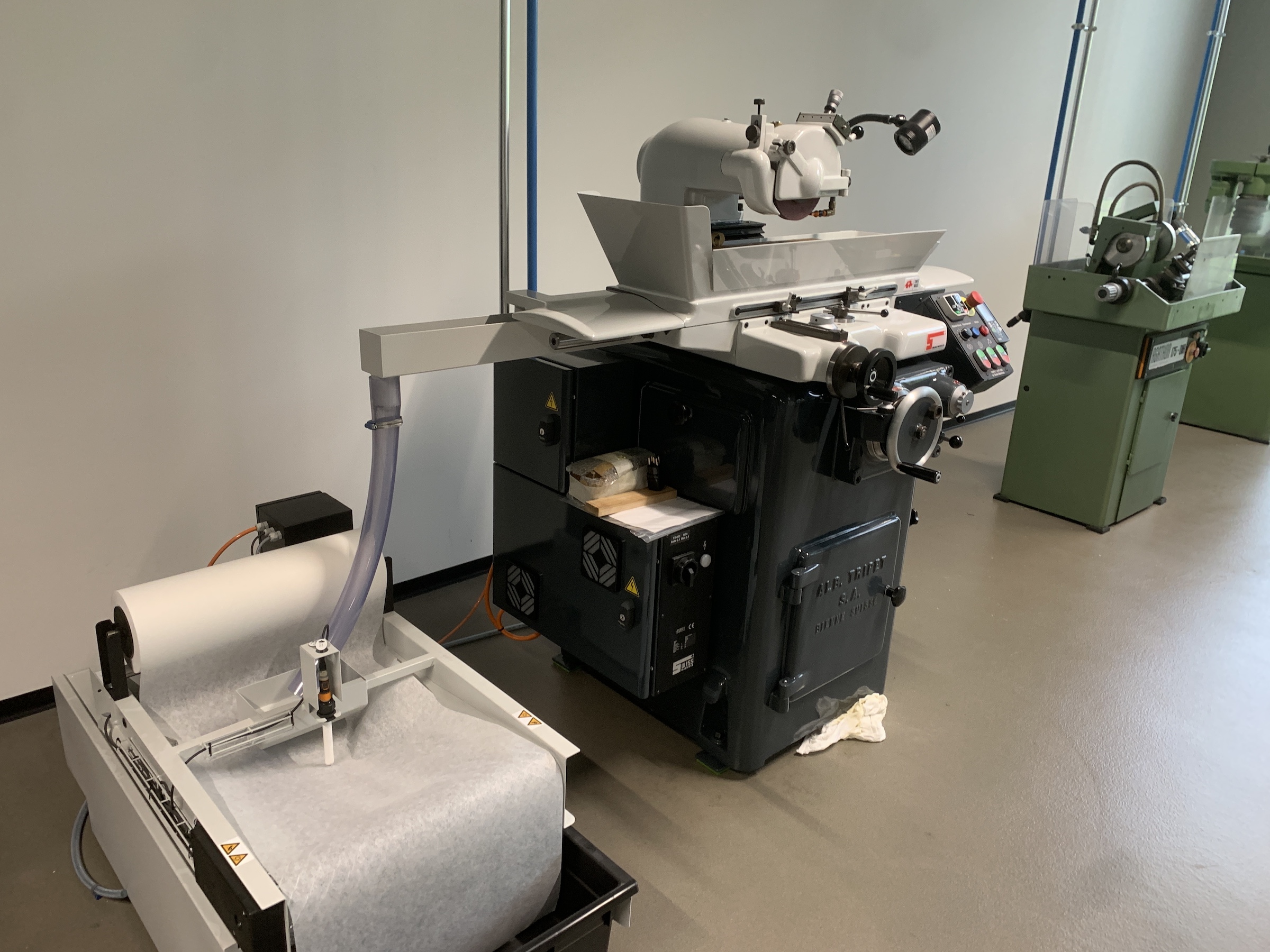

Besides a few rooms for special purposes (CNC-control room, the new laser/rapid-prototyping machines etc.), the floor is roughly divided into two areas. One for the more traditional machines – which still are needed for quite some operations – and one for the high tech stuff.

You may wonder about the part on the left on the last picture. The fleece also catches the smallest parts that fall off during the processing of gold in order to recycle them.

The last section now is the equally large «CNC-hall». Here you can see, among other things, where the large bars mentioned above are cut into workable pieces.

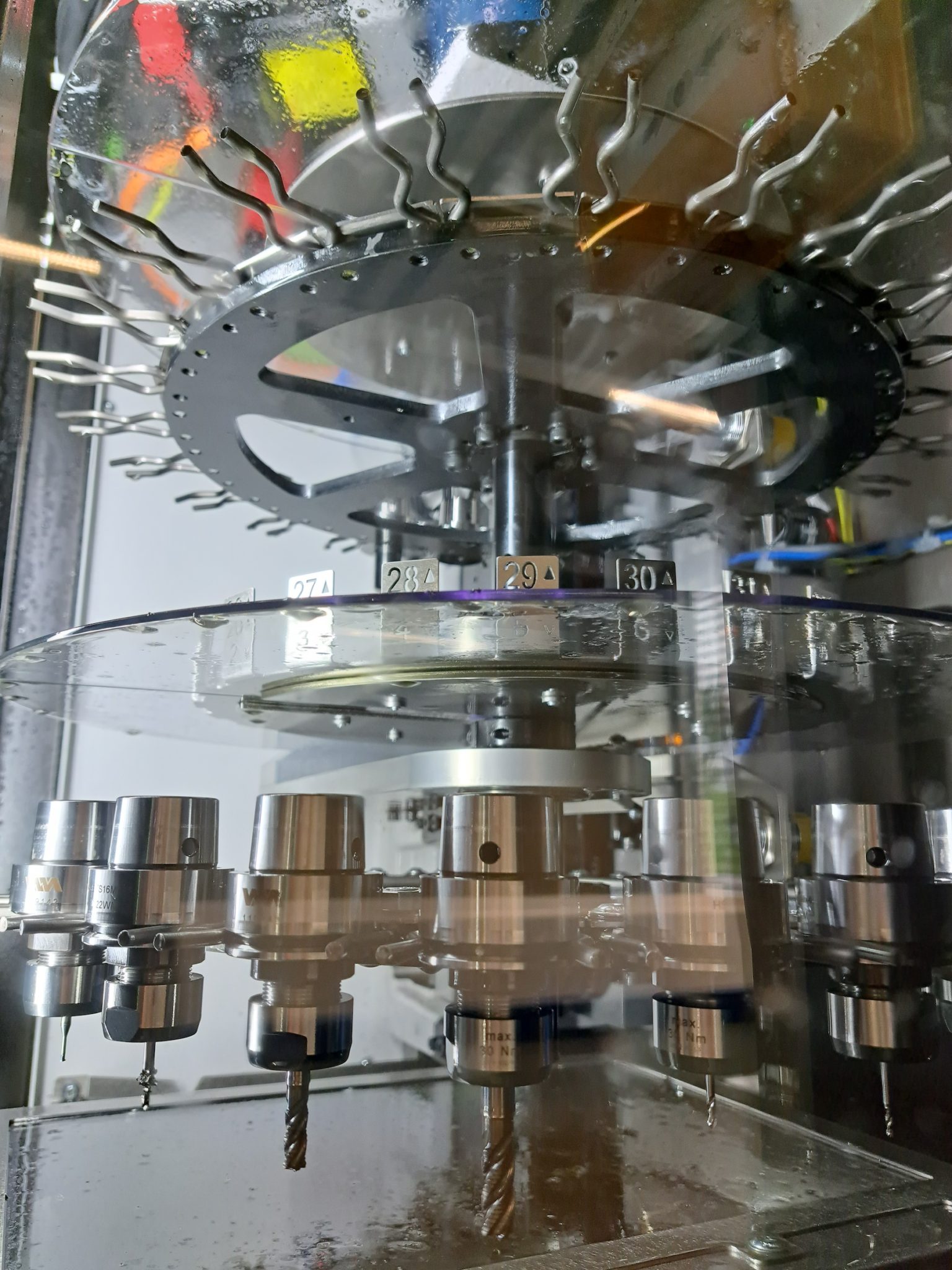

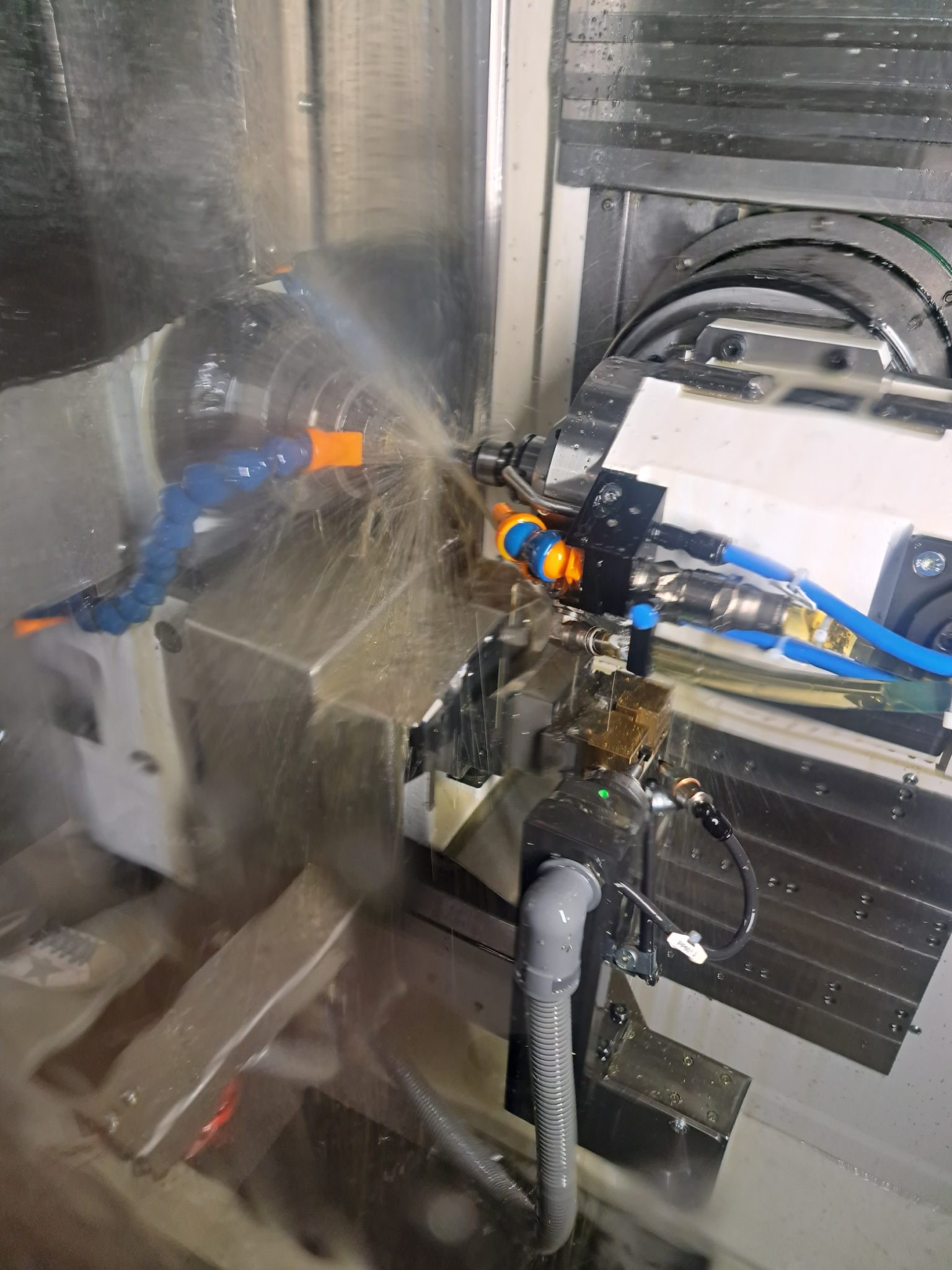

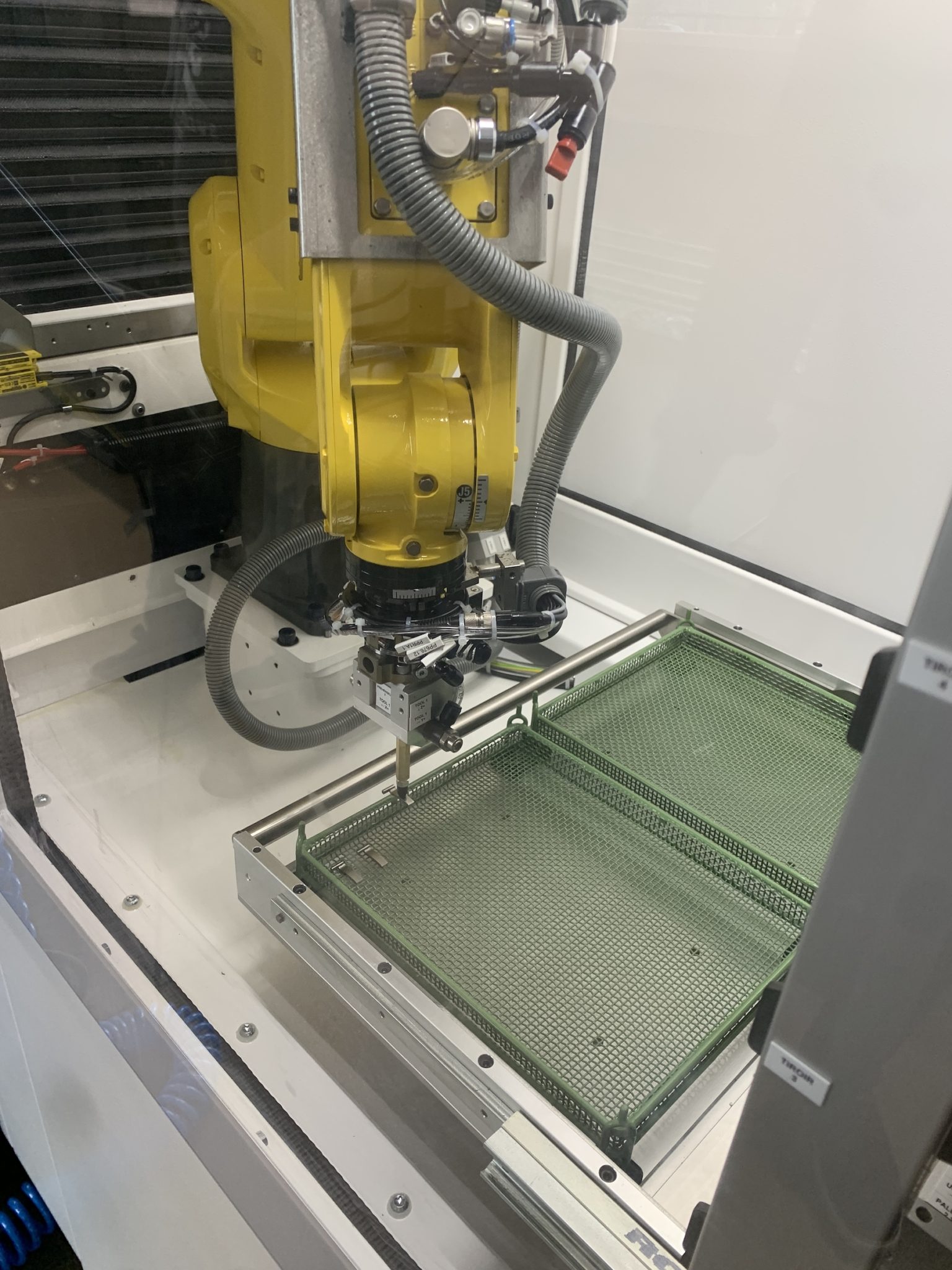

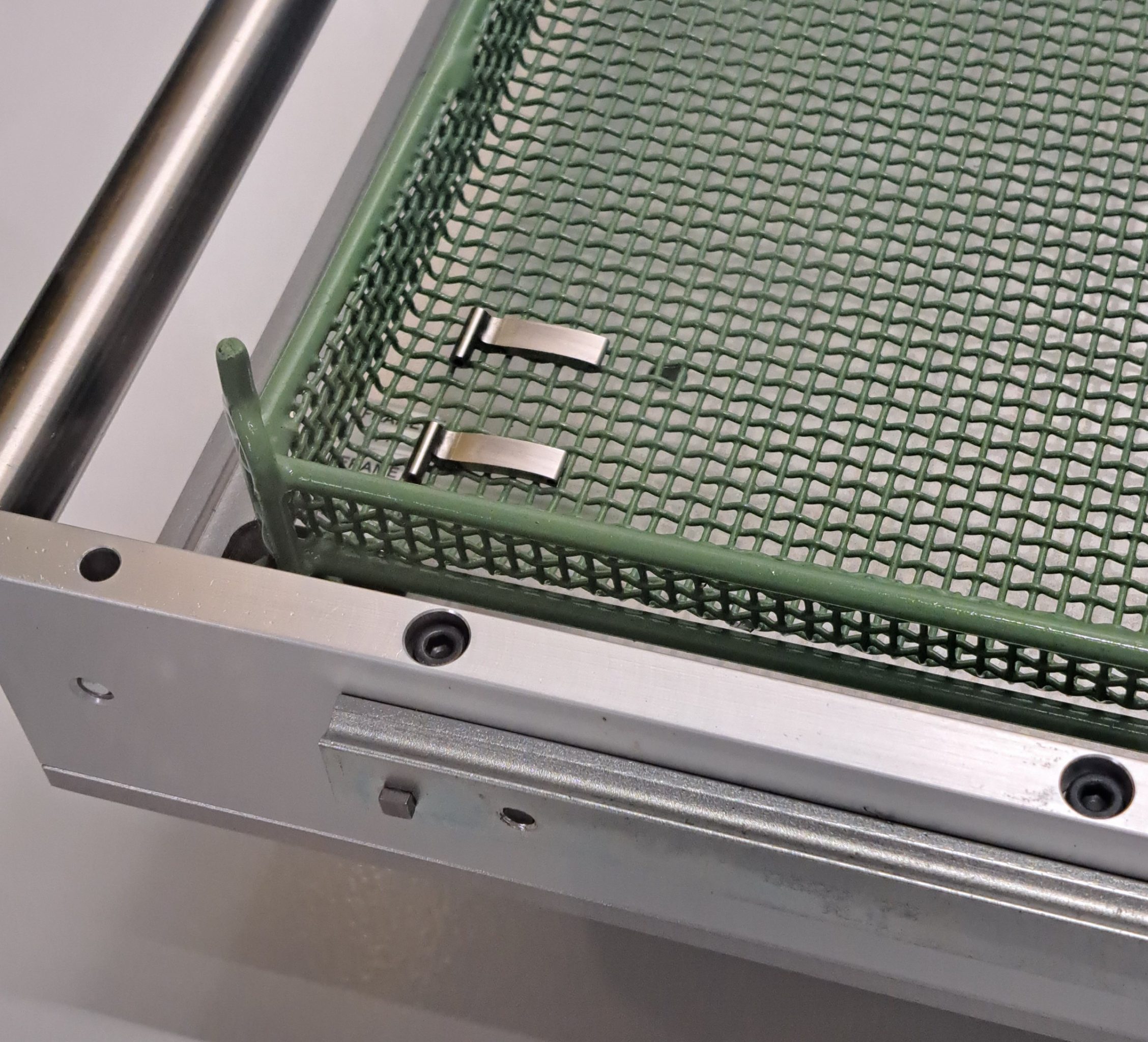

One the following pictures you can briefly see the development of a watch part from it’s technical drawing to the final piece. In one machine there is both a complex CNC milling device with a revolver of tools, but also a robot arm, which eventually places the parts in the tray in which it will be transported to the final finishing and assembly area.

During this process (as I didn’t wear a chronograph I couldn’t stop the time but it took way more than five minutes) the machine changes the tools several times, just to make one single part.

We left Formex in awe after having seen not only the deep know-how of watch design and production, but also the level of dedication which you can feel everywhere around here.

The visit to Formex and the meeting with Raphaël reminded me of a famous quote, which is attributed to Mark Twain: “Find a job you enjoy doing, and you will never have to work a day in your life.”

Although it seems that his day must have 48 hours, I had the impression, that Raphaël does not work at all. It is so refreshing to see so much enthusiasm for the subject.

We ended this tour with … well watches.

I still can’t decide, Essence Leggera with a carbon case or the Reef GMT with the interchangeable bezel …

****************************************************************************

****************************************************************************

Leave a Reply

You must be logged in to post a comment.