*) other meanings of «crazy», according to Merriam-Webster:

dreamlike, unbelievable, eccentric, Alice-in-Wonderland

!Trigger warning:

a picture is worth a thousand words: this article features more than 50 pictures full of horological craziness!

At the beginning of the year, the Fifth Wrist crew and friends took the opportunity to accept an invitation to a factory tour at Franck Muller near Geneva in the context of Watches and Wonders.

Hand on heart: did you think – at least a little bit – that Franck Muller is ever so slightly “over the top” and not always to be taken entirely serious?

Well, think again!

This factory tour did not only showed a staggering high level of vertical integration, but also of enthusiasm!

Franck Muller calls the area “Watchland”, which is by no means an exaggeration, as it measures 16,000 square meters. And this is not even taking the nearly equally impressive sales area/buildings into account which are located just 500 m away from the factory.

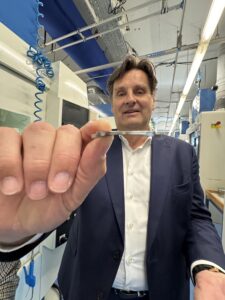

Ralf Kern, brand manager northern Europe and a genuinely nice guy, showed us around.

At the upper end of the Franck Muller Watchland, overlooking the Lake Geneva, is a listed château, where the management is based. From there, you can see the four modern but architecturally adapted production buildings on an area reminiscent of Versailles. At the lower end, towards the lake, the ensemble is completed by the diamond setting plant (Backes & Strauss).

Most of the tour took us through the four main production buildings. Seen from the château, on the right are those for parts production – i.e. the ones with the machines that smell of oil – and on the left those for the watchmakers, which are much more airy (and have wooden floors) …

We startend the tour in the château to get an impression of how the management and administration resides – very château-esque and down-to-earth at the same time.

The production area

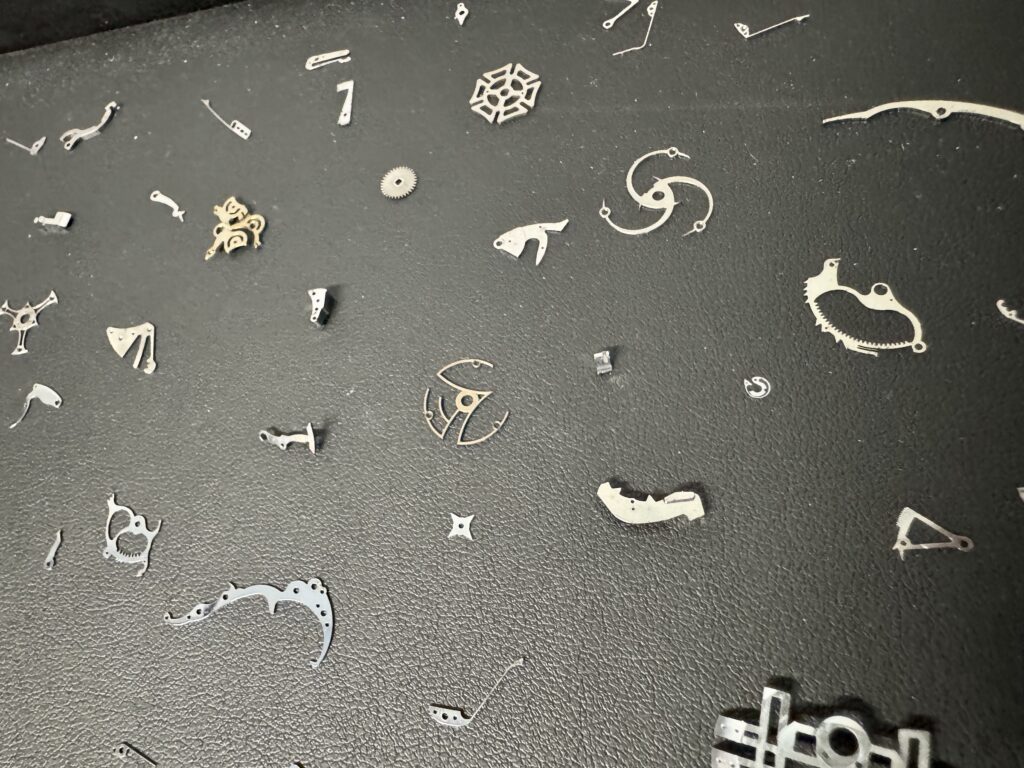

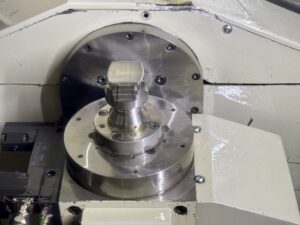

The most time, however, we spent in the production halls, where large beams of metal are magically transformed into small, tiny, minuscule objects.

I particularly like this picture as it shows various aspects simultaneously: the machinery and the technical infrastructure – and the efficient use of space – as well at the same time some hand work in the same area.

It looks like a spaceship to me … no idea, but certainly a very important part of a watch …

As we walked through the production halls, the parts got smaller and smaller. So at the beginning we were looking at the big machines and the production of cases. (click to enlarge)

A next step was the in-house (which should no longer surprise you) electroplating room, in which we spent not that much time, as you can’t see this much and you also have to be quite careful.

However, it impressively demonstrates the high vertical integration of this factory.

Right next to this, quite logical, we could have a look at one area of parts finishing, where quite a large number of rotors, bridges and the like have been refined by hand with perlage and other finishing treatments.

Here you can see a traditional machine …

… using a wooden disk to finish watch parts.

A separate room is dedicated to the production and finishing of very small parts. Here you can also get an idea of the cooperation of modern machinery and manual labour.

What always amazes me is the peaceful coexistence of state-of-the-art CNC machines and traditional tools; so I’ll leave a few pictures here:

Of course, anodising is also carried out in-house, which allows such watches to be adapted to customer requirements.

The watch assembly

When walking across the area from the production to the watchmaking / assembly buildings you again get a staggering view of the lake and the diamond setting building (behind the shed, of course, no access here!).

Although you undoubtedly see that this «watchmaking area» (rather than «parts manufacturing») looks much “nicer“, we don’t have that many pictures here, as the nature of the business mean more restrictions to getting closer.

But I guess you still get an idea of the light-flooded rooms which combine wooden floors and walls with modern ceiling and building technology.

(click to enlarge)

Movements and of course full watches are assembled here, some of them with the gem set cases from the building we’ve seen earlier.

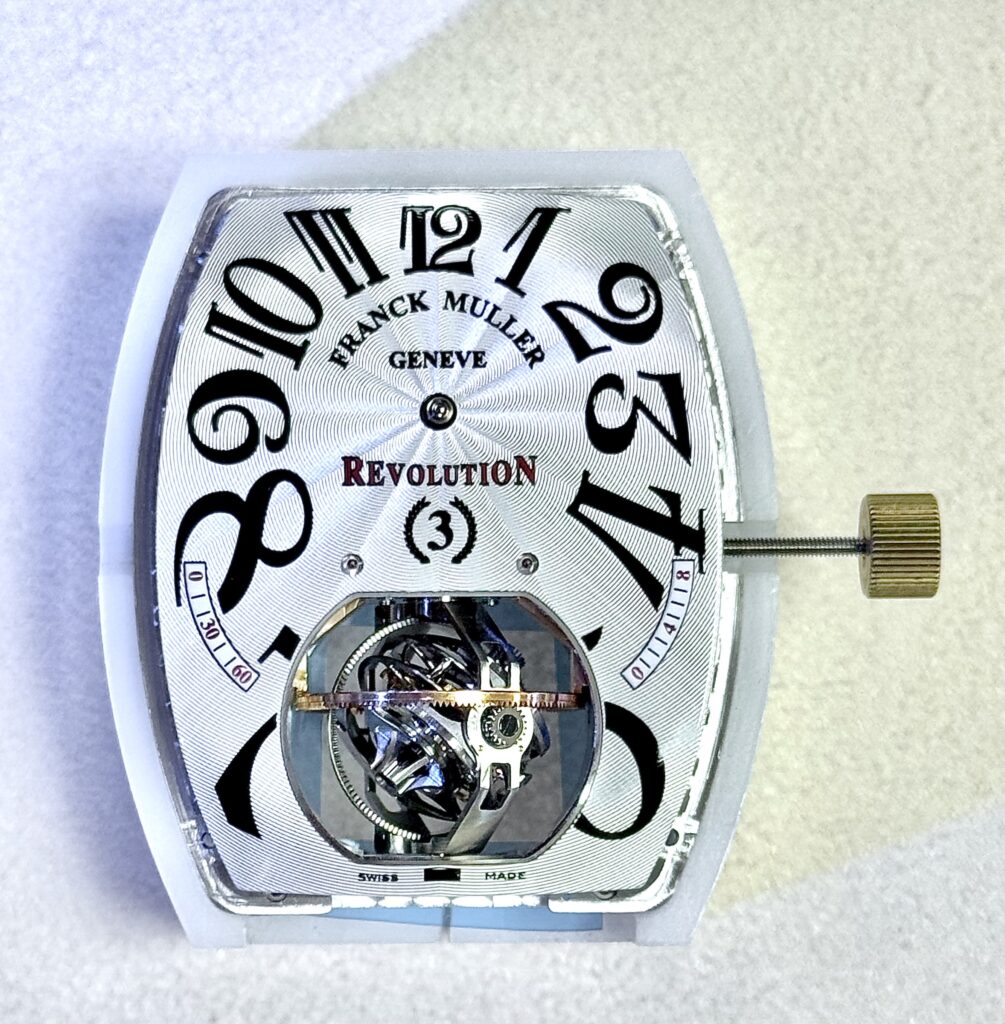

Our last station in the factory was a room in which watchmakers only get after years and years of training (well, at least if they want to work in there):

The show room

At the end of our tour we drove the very short distance to the sales area, where next to this nice other manor house you find the impressive sales room.

Here you can have a look at mind-blowing 1.000(!) different watches (economies of scale seem not to be a strategic focus of the company;-)).

Talking about numbers, Franck Muller employs about 550 people, of which 350 work in watchmaking/production and produce some 40.000 watches a year.

While this may sound like a comparatively small number, please bear in mind, that this equals to some 180 watches per working day, including super-complications like the ones below.

Thank you Franck Muller and team!

To round off this little tour through Franck Muller Watchland, here is a video of my personal favourite:

the totally crazy watch with the crazy jumping hours and date: Might as well jump

Leave a Reply

You must be logged in to post a comment.